Points To Ponder To Ensure a Perfect Laser Cutting Project

Points To Ponder To Ensure a Perfect Laser Cutting Project

As a metal fabricator, there are a lot of things that you need to consider to ensure a perfect metal fabrication project. When it comes to providing online laser cutting service, precision is the key. At MetalsCut4U.com all of our metal fabricators are highly skilled and experienced as they have a vast amount of experience.

Being a skilled metal fabricator requires knowing various tricks that are used to fabricate various different types of metals. Bad skills and techniques will result in nothing but wasting time and energy. This is why it is the best to use advanced factory automation techniques and equipment that ensures absolute consistency for your metal fabrication projects.

Laser cutting is one high-precision process which can actually help to make the end results of any product as accurate as possible. Laser cutting is also one of the safest and fastest methods of cutting sheet metal almost in any thickness.

At MetalsCut4U.com we master in configuring custom metal parts based on the requirements of our customers. We use the latest technology to fabricate any type of metal part as it ensures the most precise results. Below listed are some of the key points that are essential for executing a precise metal fabrication project

For the start of a metal fabricating project, it is required to have a sheet metal which can be cut, welded and shaped as required. This is when expert planning and cutting skills are required. Even the slightest variation in cutting will result in not being optimal. Making sure to cut and fabricate the metal sheet based on the exact measurements given by the customer is key.

As an efficient fabricator, it is very important that you use the best and latest technology for fabrication purpose so that minimum material is wasted. When you use the laser cutting method, there is almost no mechanical stress involved. This is why the cuts can be made really close to each other. Nesting different parts on one sheet to optimize the most out of one metal sheet is one step to reduce wastage.

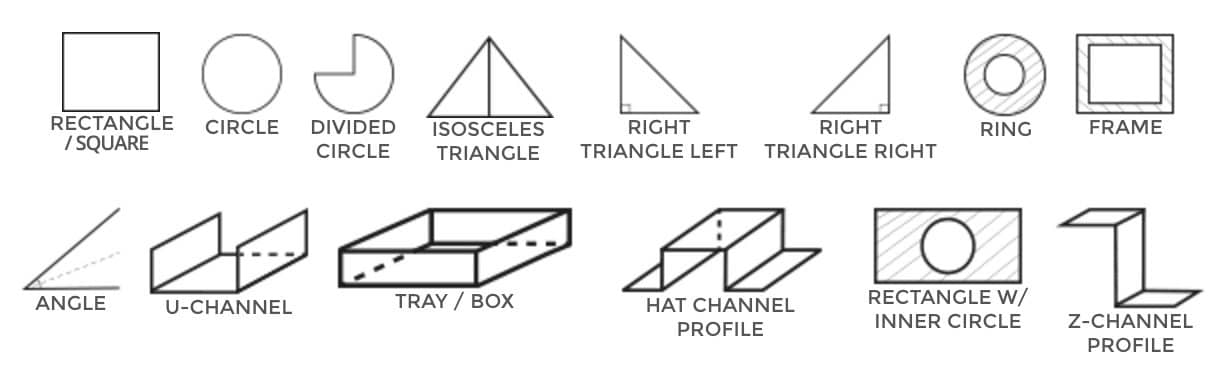

The actual cutting of metal with a laser involves minimum to no human involvement at all, this is why the rate of accidents is also reduced while using laser cutting for the fabrication process. At the same time, it needs good preparation and CAD skills to program the same. At MetalsCut4U.com we use the latest and best technology for fabricating any metal parts. Due to the fact that laser cutting is the most advanced technique not only to cut metal it can be used to cut various complex shapes even if they are very small.

The actual cutting of metal with a laser involves minimum to no human involvement at all, this is why the rate of accidents is also reduced while using laser cutting for the fabrication process. At the same time, it needs good preparation and CAD skills to program the same. At MetalsCut4U.com we use the latest and best technology for fabricating any metal parts. Due to the fact that laser cutting is the most advanced technique not only to cut metal it can be used to cut various complex shapes even if they are very small.

If you are in need of a specific metal part for the purpose of your DIY project. You can easily configure almost any shape online on our website. We make it easy for you to customize any metal part by simply following the online configuration process on our website. We specialize in fabricating single units of metal parts, unlike most other metal fabricators who only deal in bulk orders.

Make sure you check out our gallery to see some examples of metal projects we have fabricated so far for you. You can place your order on our website where you can specify all the measurements and shape requirements. From steel frame fabrication to configuring your own stainless steel backsplash, you can trust us to deliver the best.

Sheet Metal - We cut it - we bend it - we weld it - 4U!